Pole Base Delivers Concrete Predictability and Profit.

Pole Base precast light pole bases help you take back control of your job, your time, and your profit margin. Try the calculator to see how much time and money you can save with Pole Base precast light pole bases versus traditional cast-in-place (CIP) base options.

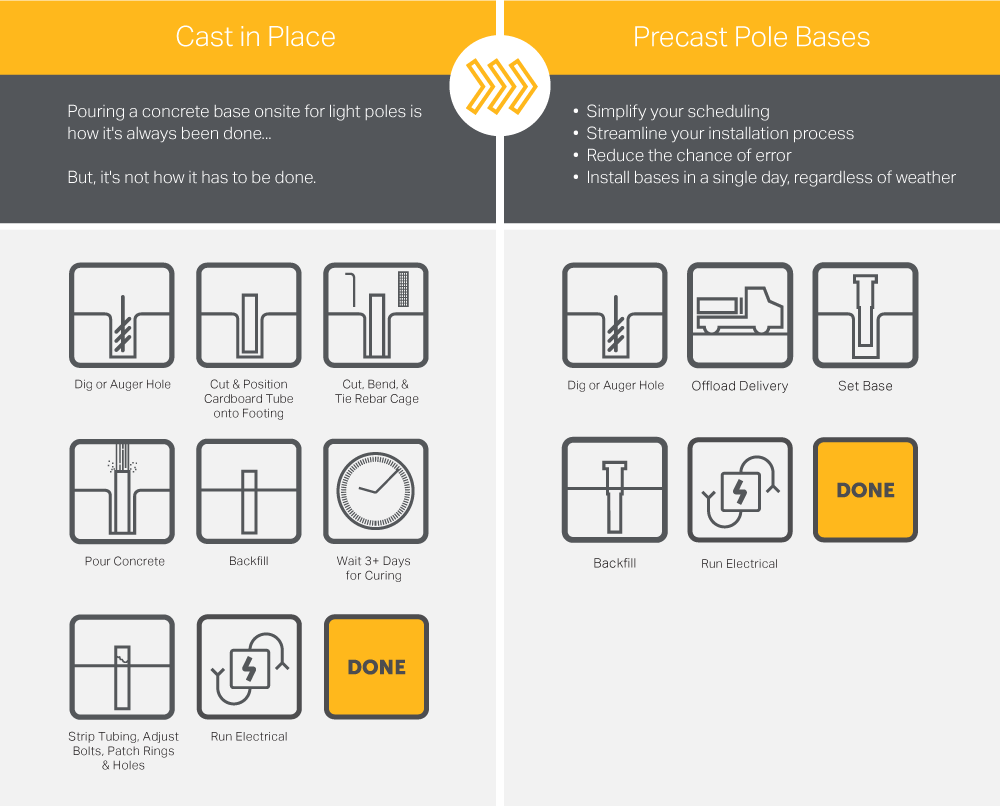

The Difference Between Precast Concrete and Cast-in-Place Concrete Light Pole Bases

Precast Concrete Light Pole Bases

Precast concrete light pole bases like Pole Base are produced offsite through the use of forms and molds. The units are then transported to the site for final installation. Pole Base precast solutions are built to your exact specifications in completely controlled production environments, and offer the advantage of installation in virtually any weather conditions.

Cast-in-Place Concrete Light Pole Bases

Cast-in-place (CIP) concrete (also referred to as “poured-in-place” or “site-cast” concrete) is a construction material produced onsite in the final location of its use. CIP light pole bases are poured onsite with the use of cardboard forms, making them susceptible to any less-than-ideal weather conditions. This may lead to delays and extensions of installation timeframes and worse, can compromise the structural integrity of the finished product.

Precast vs. Cast-in-Place Pole Base Installation

In the race for best base, it’s not even close. Pole Base ensures you cross the finish line sooner. Check out the video to see how.

Calculate your time and risk savings

Winning with Pole Base

More Predictable. More Profitable

Prefabrication ensures the bases are crafted when you need them and to your project’s specifications, including junction boxes, conduit, rebar reinforcement, and bolt patterns.

Install Anytime, In Any Temps

No more delays waiting for the weather to clear or temperatures to improve. Installation is quick, easy, and on your timetable, not Mother Nature’s.

Hours or Days? It’s Your Call

Pole Base light pole bases can host lights the very same day they’re placed in the ground. Even with optimum weather and perfect scheduling, installing lights on a cast-in-place base requires multiple days.

- Day 1 Prep the site and pour the concrete

- Day 2 Remove the tube

- Day 3, 4, 5… Wait for the base to fully cure

Superior Quality Control

A controlled production environment means the materials, mix, and curing conditions are never compromised by external factors or costly mistakes in the field. Your project gets a stronger (4,000 PSI), more consistent light pole base and you get the peace of mind that comes with it.

A Concrete Comparison

How Pole Base stacks up against cast-in-place concrete bases.

Pole Base: A Concrete Advantage for Projects Across the Country

Pole Base precast light pole foundations have been difference-makers for plenty of projects, both large and small.

Fulfillment Center Project Maximizes Savings

A 2.5 million-square-foot (233,000-square-meter) fulfillment center in Bakersfield, California, needed 135 bases for its parking lot lighting. And the bases needed to range in height from four to 11 feet (1.2 to 3.5 meters) tall. CalPortland Concrete Products (formerly Southwest Concrete Products) got it done with Pole Base.

Multi-Phase Marina Development Avoids Getting Soaked

Serious groundwater complications jeopardized the Fort Pierre, South Dakota, Riverwalk Landing marina development along the Missouri River. Pole Base precast foundations were used to safeguard against potential water table issues impacting the overhead lights illuminating the development’s 130-space parking lot.

Sports Complex Doesn’t Play Games with Mother Nature

The King Louie Sports Complex in Lousiville, Kentucky, needed high-quality lighting to illuminate its volleyball, soccer, football, and field hockey surfaces. The lights had to be installed in the midst of inclement weather and also needed to match the aesthetics of the facility. Pole Base foundations were created with a Ledgestone texture and color to match nearby amphitheater seating.