Why Use Pole Base for Distribution Center Site Lighting Projects?

Avg. Read Time: ±2 min 15 sec

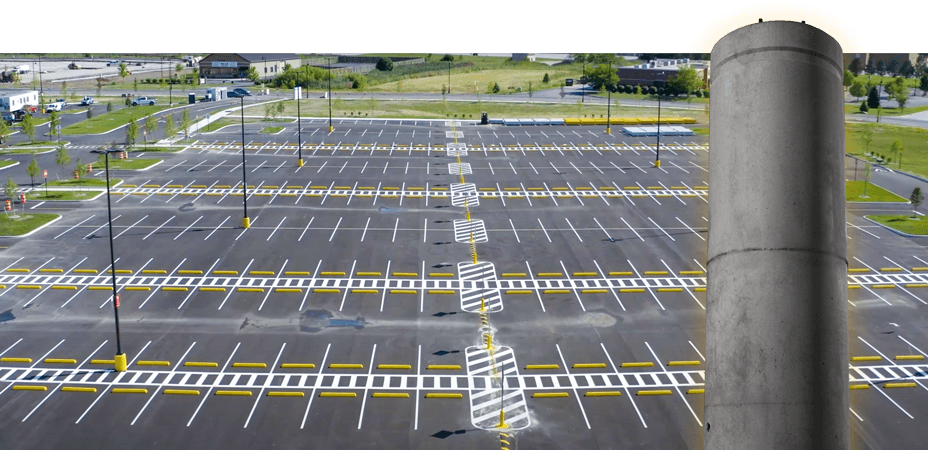

If you’ve been tasked with providing site lighting for a large-scale fulfillment or distribution center project, turn to Pole Base for a high-quality and aesthetically pleasing product. Site lighting for distribution center projects can feature expansive parking lots, driveways, and loading areas that require lighting solutions manufactured according to each site’s conditions. You’ll want a solution that works for you, installs without a fuss, and pleases the project’s owners.

The Pole Base-ics

Short on time? Here are this article’s key takeaways…

Impress project owners on distribution center projects with the look and efficiency of precast bases.

Bases are delivered to the job site ready to install and can be installed in most weather conditions.

Pole Base installs in a fraction of the time it takes to install cast-in-place alternatives keeping projects on schedule.

Installing large quantities of precast bases saves you time and money.

Pleasing Project Owners

Distribution center project owners face the challenges of any major commercial construction project but often on a larger scale. Coordinating contractors, overcoming weather setbacks, and trying to keep the projects on schedule and budget is difficult enough with smaller projects, but when it’s a sprawling warehouse, those issues can get big in a hurry. To minimize these challenges, project owners seek the most efficient contractors and high-strength products to ensure their project moves forward with minimal hiccups. Impress project owners with the efficiency of installing precast bases while providing a product with aesthetic appeal and structural integrity.

Built to Spec

Arriving at the job site complete and ready to install, each Pole Base is built to the specifications required by the project’s engineers and includes rebar reinforcement, conduit, and anchor bolt placement. With aesthetically pleasing finishes including the Round Rusticated and Round Smooth textures, contractors can provide a sightly finished product.

Pole Base producers meticulously cast bases in sizes ranging from 12- to 36-in (304.8 to 914.4 mm) diameters, with lengths up to 13 ft (3.96 m), all in a completely controlled environment. This precision ensures that bases show up on your jobsite ready to go, saving you precious time that would otherwise be wasted installing cast-in-place base alternatives on-site.

More Pole Base = More Savings

When it comes to distribution center projects, anywhere from 12 - 100+ light pole bases may be required. Installing Pole Base is a plug-and-play process on large-scale applications, offering contractors the speed and simplicity they need. On the other hand, assembling and installing with cast-in-place cardboard tube bases on-site can be a time-consuming task, requiring nearly seven times more man-hours than a single precast base. Moreover, cast-in-place often results in a less-sightly product, as cardboard tubes leave rings and surface imperfections on finished bases. By choosing precast Pole Base, you not only save time, but also ensure a high-quality finished product, enhancing the overall aesthetics of your project.

The Conclusion

Looking to be the hero of your next distribution center project? Look no further than Pole Base's precast bases! With Pole Base, you can save time and resources, and still achieve an attractive end product.

Pole Base Installation Helps Save Time & Money On Fulfillment Center Project Location: California, USA

Contractor Chooses Pole Base for Distribution Center Site Lighting Project Location: Toledo, OH

![Pole-Base_Light-Pole_Round-Smooth_Amazon-Fulfillment_18_3-Column_[Landscape]_600x300.jpg](https://aster-brands.imgix.net/polebase/Pole_Base_Light_Pole_Round_Smooth_Amazon_Fulfillment_18_3_Column_Landscape_600x300_8745928702.jpg)